-

Posts

1,801 -

Joined

Content Type

Profiles

News

Store

Downloads

Everything posted by TRIFECTA Performance

-

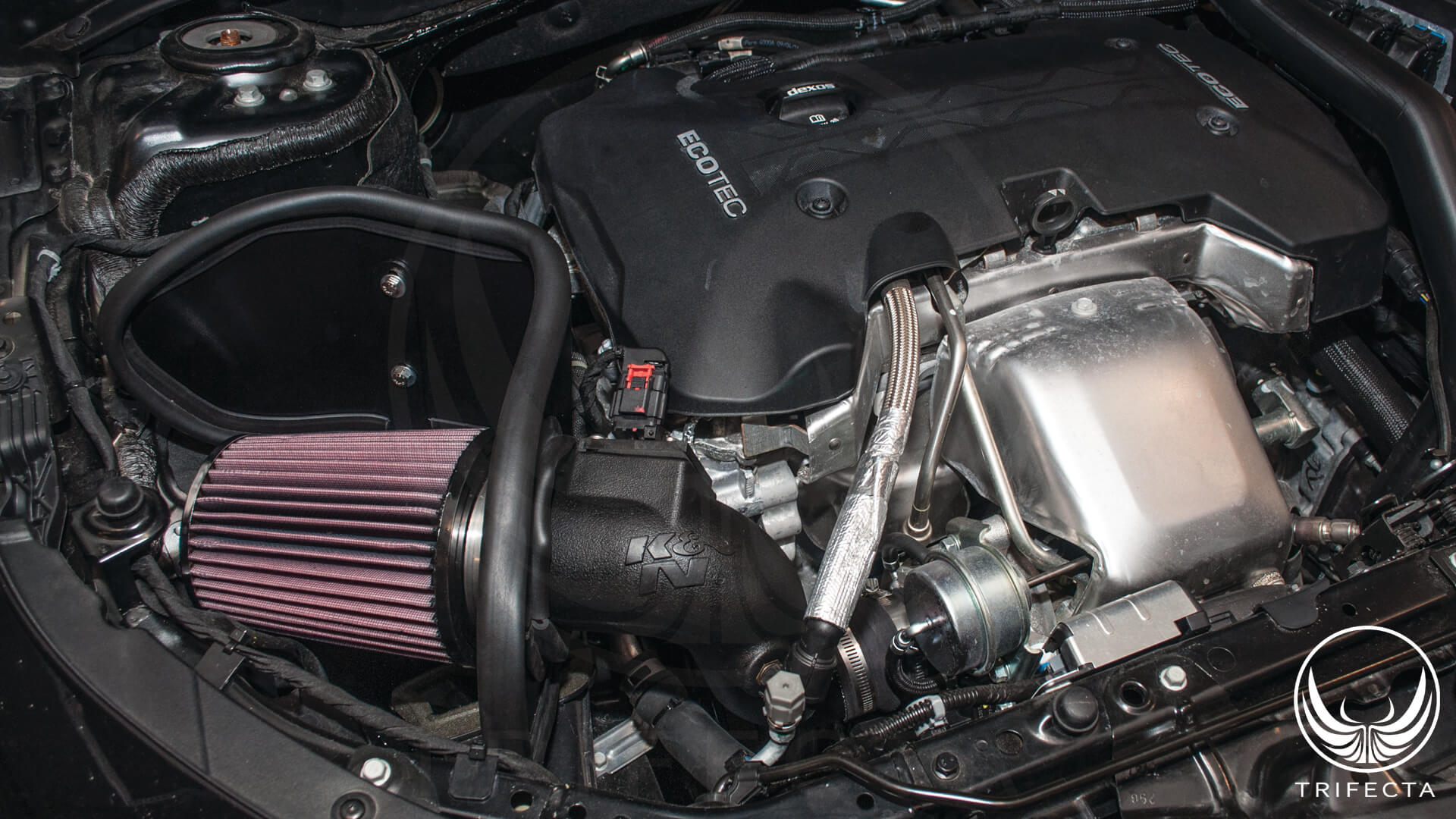

An HSN** means that the part was installed and tested for correct functionality on a TRIFECTA development vehicle, with the TRIFECTA calibration product, and if any specific calibration changes are necessary to support or optimize it, these changes have been established and finalized. As such, customers wishing to install this part on their vehicle may do so under the Advantage line product and will not require any customization beyond, in some cases, a parts-specific calibration update. The following is the manufacturer's description of the product: (For full info, please see the manufacturer's website here: MPFab Intake System for 2011-2015 Chevy Cruze 1.4L Turbo) During our testing, we found this intake system to deliver accurate airflow metering with the OE mass air flow calibration meaning this intake can be used with our without a performance / custom tuning / calibration. We found the sound and the quality of the kit to surpass most of the other mass market intake systems available for this vehicle. Future or existing TRIFECTA customers interested in purchasing this product may be able to do so through TRIFECTA, please contact our support team for more info! **Please note: A Hardware Support Notification (HSN) from TRIFECTA is a statement that we tested the product with our calibration products, and in some cases may include performance data collected and/or ad-hoc comments on the product by TRIFECTA. TRIFECTA is not specifically affiliated with, nor specifically endorses (or is endorsed) by the product listed in this HSN. TRIFECTA makes no warranty or claims regarding the quality or performance of the product listed in an HSN. In some cases, TRIFECTA may act as a reseller of hardware described in an HSN and as such may receive a profit by reselling said hardware. TRIFECTA always recommends that hardware be installed by an experienced and certified shop or facility. Unless otherwise specified, customers purchasing hardware from TRIFECTA would need to work directly with the manufacturer in the event there is a question regarding installation. Unless otherwise specified, all hardware available through TRIFECTA will “drop ship” from either the manufacturer, or a distributor.

-

A Word About Manufacturer Warranty and Aftermarket Modifications

TRIFECTA Performance posted a article in News

Some consumers choose to modify their vehicles, for many reasons. In some cases, it's to add or enhance function (e.g. a truck lift kit to provide better off-road clearance). In other cases, it's to customize the look of the vehicle (e.g. aftermarket wheels and tires, lowering suspension, etc.). And in some cases, it's to enhance the performance of the vehicle (e.g. aftermarket 'tuning', exhaust system upgrades, cold air intake systems). So, the question becomes: Is a vehicle manufacturer obligated to cover “warranty issues” on vehicles that have been modified with parts or software that were not designed by the manufacturer? The short answer is “yes, so long as the warranty claim is for a part which is shown to have a manufacturing defect.” However, given the increasing complexity of vehicle designs and the inter-dependence of cross-vehicle systems and components, it's getting easier for the manufacturer to claim that ANY modification could have wide-reaching consequences and lead to the failure of a part which is, in fact, not defective. We commonly joke about manufacturers denying a warranty claim because of the installation of aftermarket lug nuts, but here's an example of how a manufacturer might rationalize this: Let's say there's a wheel hub bearing failure. The vehicle is towed to an authorized service center, they inspect the vehicle and find there are aftermarket chrome lug nuts installed. At this point they could reasonably claim that the aftermarket lug nuts are not known to be manufactured to the same weight, and balance tolerances that the factory lug nuts use, and as such, their installation lead to unusual forces on the wheel hub bearing which lead to its “unnatural” failure. As such, the warranty claim is denied because there's a plausible theory as to how the bearing failure could in fact be due to the installation of an aftermarket part. It would be in the domain of the vehicle owner to prove the manufacturer's theory is false. The above scenario is assumed to be fictional, but this one appeared in automotive media in 2016: A customer buys a brand new Chevrolet Silverado pick up truck, and as part of the sales contract purchases an aftermarket frame lift kit for the truck, which is installed by the dealership. After he takes delivery of the truck, he drives it for some period of time, then the Service Airbag light comes on. He brings it in for service at the same dealership that he purchased the truck from and to the very service department that had installed the lift kit. The dealership refuses to fix the issue under warranty. The stated cause? The aftermarket lift kit caused changes in the way certain airbag sensors operate (because the suspension and frame geometry were modified), causing a false-positive condition in the airbag sensor diagnostics. In both of these scenarios, it would be difficult (and expensive) to push back on these assertions the manufacturer is making. At the same time, it also leads one to wonder whether the manufacturer ever engages in abuse of this power? At the end of the day, it's murky, because in some cases, vehicle owners are trying to stick the manufacturer with the cost of making warranty repairs to the vehicle that they almost certainly caused via modification, and in others the manufacturer is hiding behind the aftermarket parts argument to avoid making repairs to a legitimately defective part. In some cases, a dealership service department may even have incentive to refuse to honor a warranty claim when they could, by procedure, have it honored. The economics behind a dealership service department are not well known, but it is possible that service departments receive a different compensation rate from a warranty claim than they would from a direct-pay customer. The following scenario may illustrate this: The owner of a new (and warrantied) Chevrolet Cruze buys and installs an aftermarket intake system. He gets the vehicle tuned by an aftermarket company. At some point later, one of the pistons fails and replacement is required. The piston failure issue is a WELL known and WELL documented issue with this engine, and between the dealership and the manufacturer there would be almost no question that this failure is in fact because of whatever defect leads to the failure in the first place (which the manufacturer has made no formal statement on). However, instead of repairing this vehicle under warranty, the dealership instead effectively cancels the rest of the power train warranty and says the modifications to the vehicle are the cause of the failed piston. This vehicle owner now has no power train warranty left, and is on the hook to pay for piston replacement. Is this treatment justified? Or is it an abuse of power? Again it is murky. Dealership service centers are the “gatekeepers” in many cases to the policy of what gets fixed under warranty and what does not. They are the ones that may make the decision to look deeper (or the manufacturer may request it). When an obviously-modified Cruze comes in with broken pistons, whether its a known issue or not, the very fact the car is visibly and obviously modified may give cause to look into it deeper (or flat out deny the claim on the basis alone). If it's what appears to be a completely stock Cruze with broken pistons in the manner described in the technical bulletin, there's likely to be no question about it. The level of aggression the manufacturers might display in this regard is almost certainly related to the cost of the warranty repair. It's one thing for the manufacturer to be looking at having to replace pistons in a 4 cylinder engine, it's quite another to be looking at having to replace an entire V8 diesel truck engine because there's a connecting rod hanging out of the side of the block. As such, manufacturers have taken up certain countermeasures, some are known publicly, to identify when a vehicle has been tampered with, be it via hardware (parts), software (tuning) or some combination thereof. On top of that, there's been (as far as we know, unsubstantiated) rumors that manufacturers are even turning to social media to identify people who have openly discussed modifying their cars. Unfortunately, nobody in the aftermarket can ever be sure what tampering countermeasures are being taken by the manufacturer at any point in time, nor what countermeasures may be taken in the future. Nobody can be sure what “non official” countermeasures are being taken, either. A good example of this is GM's OnStar. Think of your vehicle as having a communications backbone, for all the ECUs to communicate with one another, as well as diagnostic tools and aftermarket flashing tools. The OnStar module can effectively operate as a bridge between your vehicle's network and GM's OnStar network in any location that the OnStar's connection to the network can be established (it operates over the cellular phone network). This means, on a technical level, at least, anytime an ECU in the vehicle is flashed, as long as the vehicle is active on the OnStar network, the manufacturer may know about it, and/or make a log of it. They may even know the contents of the flash itself. The above scenario is unproven, just a technical analysis of what's possible, but here's another one that shows to what extent countermeasures may be deployed. On the diesel truck engines, massive gains can be made in power with just tuning alone, mainly by changing the fuel rate and increasing the turbocharger boost. With the availability of low-cost commodity tuning software, one could recalibrate their diesel truck for about $500 plus the cost of a laptop computer. No training in diesel tuning is required. The unfortunate reality is that while it's “relatively straightforward” to make more power with tuning in your diesel truck, to do so reliably requires a much higher level of engineering skill, in some cases outside the scope of what the factory ECU software is even capable of. The manufacturer started getting suspicious when they saw all of these diesel truck engines coming in for warranty repair with melted pistons. Suspecting they might be caused by poor quality aftermarket recalibration, they devised a new technique for identifying whether the tuning had been tampered with. They added a new parameter to the transmission control module where it would record and “remember” the highest amount of torque the transmission was subjected to. How does this work? The engine control module has to estimate how much torque it's making mainly for the purpose of having the transmission shift with the correct amount of line pressure and also with regard to the traction control system operation. Every time the engine controller transmitted its estimated torque output to the transmission controller, the transmission controller would compare the value to the previous highest value, and if the new value was higher, it'd remember that one. The new procedure involved scanning this parameter out of the transmission controller if melted pistons in a diesel engine showed up at the service center. This number SHOULD never be higher than the factory specs of the engine, and if it was, it was considered possible evidence of tampering. The bottom line is there are upwards of 70 ECUs in modern day vehicles, and any one of them is capable of reading (and storing) information transmitted by other ECUs. Tampering “counter-countermeasures” of any type may afford some protection against abuse of power by an over-zealous (or morally impure) service center, but ultimately if there's some sort of suspicious vehicle component failure despite the lack of any evidence of modifications, the service center will almost certainly try to use social engineering to find out if the vehicle is or was modified previously: “Have you ever tuned this vehicle?” “Have you ever installed any performance parts on this vehicle?” “Our techs found some anomalous ECU data string widget constructs and say it was tuned.” “Are you Joe Smith on Facebook also?” Questions and statements like these put the vehicle owner in a potentially tricky situation. If it was modified, and they tell the truth, their warranty's probably gone and they're on the hook for repairs. If they lie about it, then they may have just committed fraud. Refusal to answer the questions at all may be construed as suspicious as well. The only true way to be sure the manufacturer power train warranty remains in effect for the full duration with regard to aftermarket modifications, is to not aftermarket-modify the vehicle. Not even the lug nuts. -TRIFECTA Performance, Inc. -

TRIFECTA: Test results of Racer X LUJ/LUV intake manifold

TRIFECTA Performance posted a article in News

Figure 1 – Racer X Manifold for the 1.4L Turbo (RPO:LUJ/LUV) Summary We found, with appropriate recalibration, the Racer X Fabrication intake manifold increases power as measured on the dyno, by up to 12 horsepower as measured at the wheel. Torque output peak was unchanged, but did shift up the RPM band by about 200 RPM (e.g. it took 200 RPM more to reach peak torque). Figure 2 – Dyno sheet showing Stock vs Racer X performance Beyond the power gains, it is our opinion this product will be popular in this market because it also permanently and effectively addresses the PCV issues this engine is known for, provides a custom upgrade part (and look) for these vehicles, and also allows for future expansion, as there are several unused ports in the end of the manifold which could be utilized for additional instrumentation, or water, water/methanol, and/or nitrous injection directly into the manifold. Comparison to Ported Intake Manifold (OE) Prior to the arrival of the Racer X manifold, the only other intake manifold modifications that had been widely used were the porting of the intake runners of the stock intake manifold, the so-called ported intake manifold, and the PCV system modification. Figure 3 – Stock Intake Manifold with “air tumblers” The OE intake manifold has a restriction in the runner near the intake port. It is believed these are actually air tumblers and are meant to induce intake charge swirl for more efficient combustion. However, it is also theorized that these air tumblers reduce and restrict airflow when higher levels of airflow are introduced (e.g. turning up the boost, upgraded turbocharger, etc.). We had performed a preliminary test on a ported manifold versus a stock manifold several years back and saw negligible change in power on the dyno, but a possible loss of efficiency (more timing advance was required to maintain similar power levels to unported manifold). Ironically, while the effect is the ECM reports the power output level has increased due to the additional timing advance (despite a wash on the dyno), the loss of efficiency could be attributed to less efficient mixing of the air and fuel charge due to the lack of tumblers, but a more conclusive test is needed. Figure 4 – OE Ported Intake Manifold The PCV system modification addresses PCV system failures that are prevalent on this engine by utilizing an external, and more robust check valve for introducing PCV vapors back into the intake manifold. This is achieved by installing a brass fitting in the bottom of the PCV chamber in the intake manifold, routing the PCV vapors either to a throttle body spacer, or the brake booster fitting. Figure 5 – OE Manifold PCV Modification While both of these modifications are popular in the community, they are also considered do it yourself (DIY) modifications which require special tools and skill. At the time this test was conducted, we did not have a ported intake manifold available, but we plan to do a comparison to it in the future. TRIFECTA Calibration Support We are pleased to announce immediate and full support for the Racer X manifold for the GM 1.4L turbo engine in our full custom calibration tier (Elite). Additionally, we will offer a free update for any TRIFECTA customer of record on or before 05/31/2018, regardless of which product tier they purchased! Test Vehicle The test vehicle is a 2016 Chevrolet Cruze Limited LT, equipped with the 1.4L Turbo engine (RPO: LUV), and the six speed automatic transmission. The vehicle has approximately 18,500 miles on the odometer, and aside from the manifold is also equipped with a catless down pipe, cat less mid pipe, and K&N cold air intake system. There were no other pertinent modifications to the vehicle. “92 octane” fuel, considered premium unleaded in the Seattle, WA area was used for all tests. Figure 6 – Test Vehicle Test Procedure In order to keep the test results as accurate as possible, we tested both manifolds on the same day, on the same vehicle, on the same chassis dyno, back to back. We tested the Racer X manifold first, since we had installed it previously for calibration procedure. After performing several test “pulls” on the dyno, in manual 4th gear, we let the car cool down, installed the stock manifold, warmed it to operating temperature, and performed several test “pulls”. From the beginning of the test procedure, to the end, the ambient air temperature only changed about 2*F. The dyno used was a Dynojet 424xLC all wheel drive dyno equipped with eddy current load cells (but were not used for the test). The vehicle was operated in manual 4th gear for all test pulls. After the dyno brake was released, the vehicle was put in manual 3rd gear, run up to 20 MPH, shifted to manual 4th gear, then decelerated to 1100 RPM, and then a wide open throttle maneuver was executed. The vehicle was operated until 6200 RPM, and the dyno “pull” was concluded. Figure 7 – Test Vehicle on the dyno, with Racer X manifold Installation The installation of this manifold is fairly straightforward, but isn't 100% “reversible” (more on this later). The manifold has an optional PCV system “add-on”, but we couldn't see how this manifold could be installed without it, unless one chose to simply vent PCV gases to the atmosphere, or perhaps someone wanted to fabricate their own PCV solution. Installation requires transferring (from the stock manifold): 1. The fuel rail and fuel injectors to the new manifold, 2. The EVAP solenoid, and 3. The Manifold Absolute Pressure (MAP) sensor. The installation instructions also call for retaining the turbo bypass valve (BPV) control solenoid so the Engine Control Module (ECM) won't set the check engine light, but we chose to skip this step and devised a means of installing the manifold without the BPV control solenoid without any negative effect via the ECM calibration. While we say this kit isn't 100% “reversible” (more like 90% “reversible”) it's of little consequence, in our opinion, because it would be unlikely an end customer would want to, or ever go back to their stock intake manifold. It's not fully reversible, because it requires cutting of some of the hard plastic lines that route to the brake booster and the PCV vent to the turbocharger inlet in order to complete installation. Initial Test Drive Our test vehicle was equipped with the production TRIFECTA Advantage calibration. On the first test drive, we noticed two issues with the vehicle, one was a hesitation and “dip” in power, in some cases accompanied by audible spark “knock” in the 5000 RPM range under full acceleration, and what seemed to be a somewhat laggy pedal response. While the manifold manufacturer states the manifold will work without issue on the stock calibration, it was clear to us that some additional calibration work would be needed for vehicles that have a more powerful aftermarket calibration. One net effect of using this intake manifold, which sports a larger intake plenum volume than the factory intake manifold is that actual manifold pressure levels end up lower than stock (while moving a higher amount of airflow due to flow and efficiency improvements). These changes in airflow and pressure dynamics showed us more in depth recalibration would be required. Dyno Calibration Session We spent most of a full day addressing the vehicle performance issues we had noted previously (the most time consuming being the full recalibration of the wastegate duty cycle table). We were able to resolve all of the performance issues and were able to regain the throttle response we experienced with the stock manifold. After completing the dyno calibration session, and resolving some minor calibration issues with street testing, we put approximately 1000 miles on the vehicle as a short term reliability test. No further issues were experienced. Airflow and Pressure Statistics When we performed the final back to back test on the dyno with the Racer X manifold vs the stock manifold, the following airflow and pressure statistics were observed: Airflow (mass air flow sensor) lb/min, 6020 RPM and Manifold Absolute Pressure: Compressor inlet pressure: 98 kPa RacerX: 18.55 lb/min, 211 kPa (113 kPa, 16.385 psi boost) Stock: 18.32 lb/min, 227 kPa (129 kPa, 18.705 psi boost) At 6020 RPM, in both cases, maximum pressure is obtained from the compressor. However, despite the manifold being at almost 2psi less boost pressure RacerX vs stock, the airflow is still higher, which is a more accurate measure of performance. We also sampled the data at 5500 RPM, the airflow differences were more pronounced (with similar manifold pressure): Compressor inlet pressure: 98 kPa RacerX: 18.62 lb/min, 229 kPa (131 kPa, 18.995 psi boost) Stock: 17.52 lb/min, 225 kPa (127 kPa, 18.415 psi boost) Conclusion Our testing has shown this product increases power, addresses several long-term issues with this platform (PCV system issues) all while offering a unique and customized look to the enthusiast's Chevrolet Cruze or Chevrolet Sonic! We believe it will continue to be a popular choice for people seeking the best for their vehicle! -

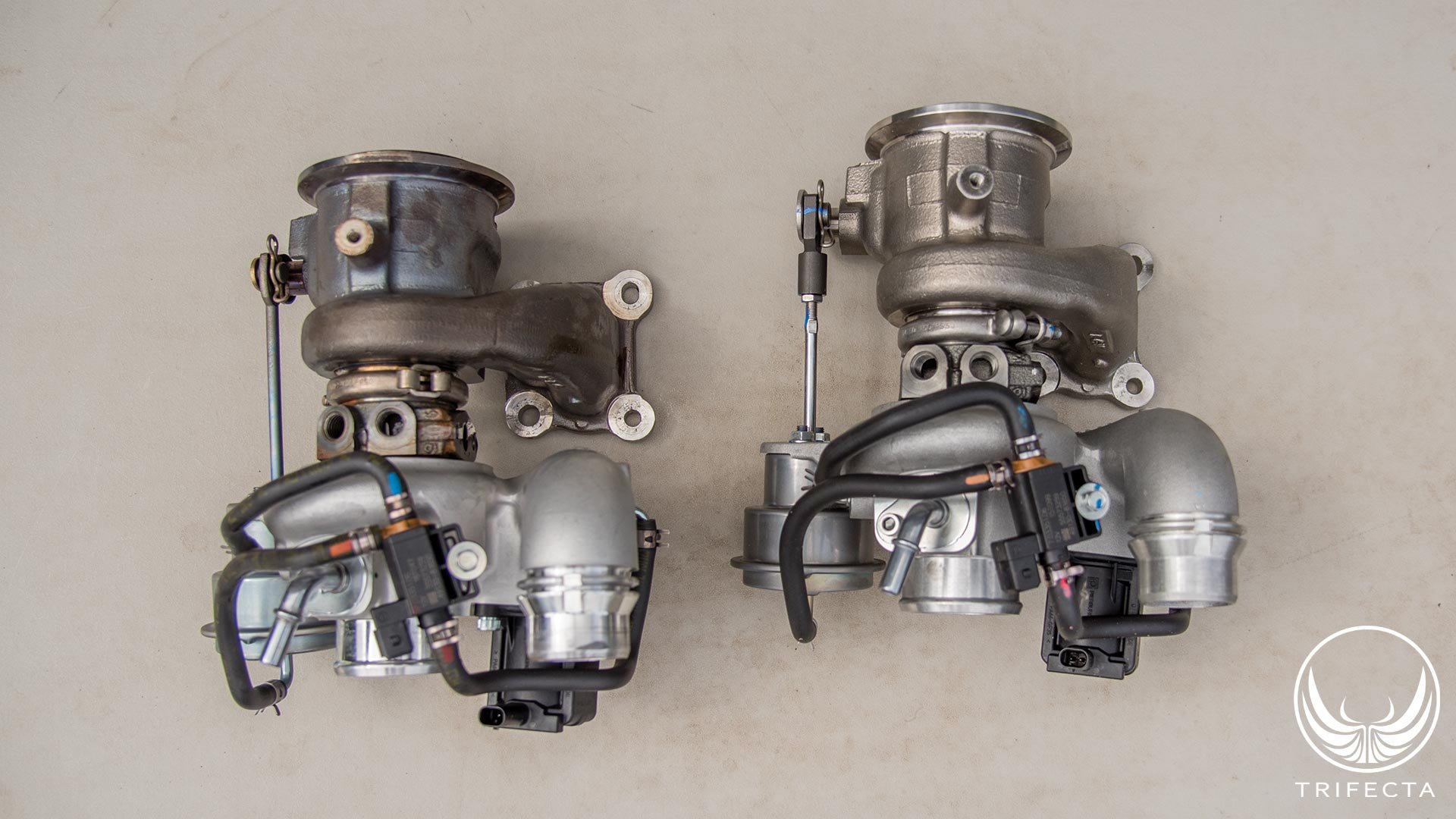

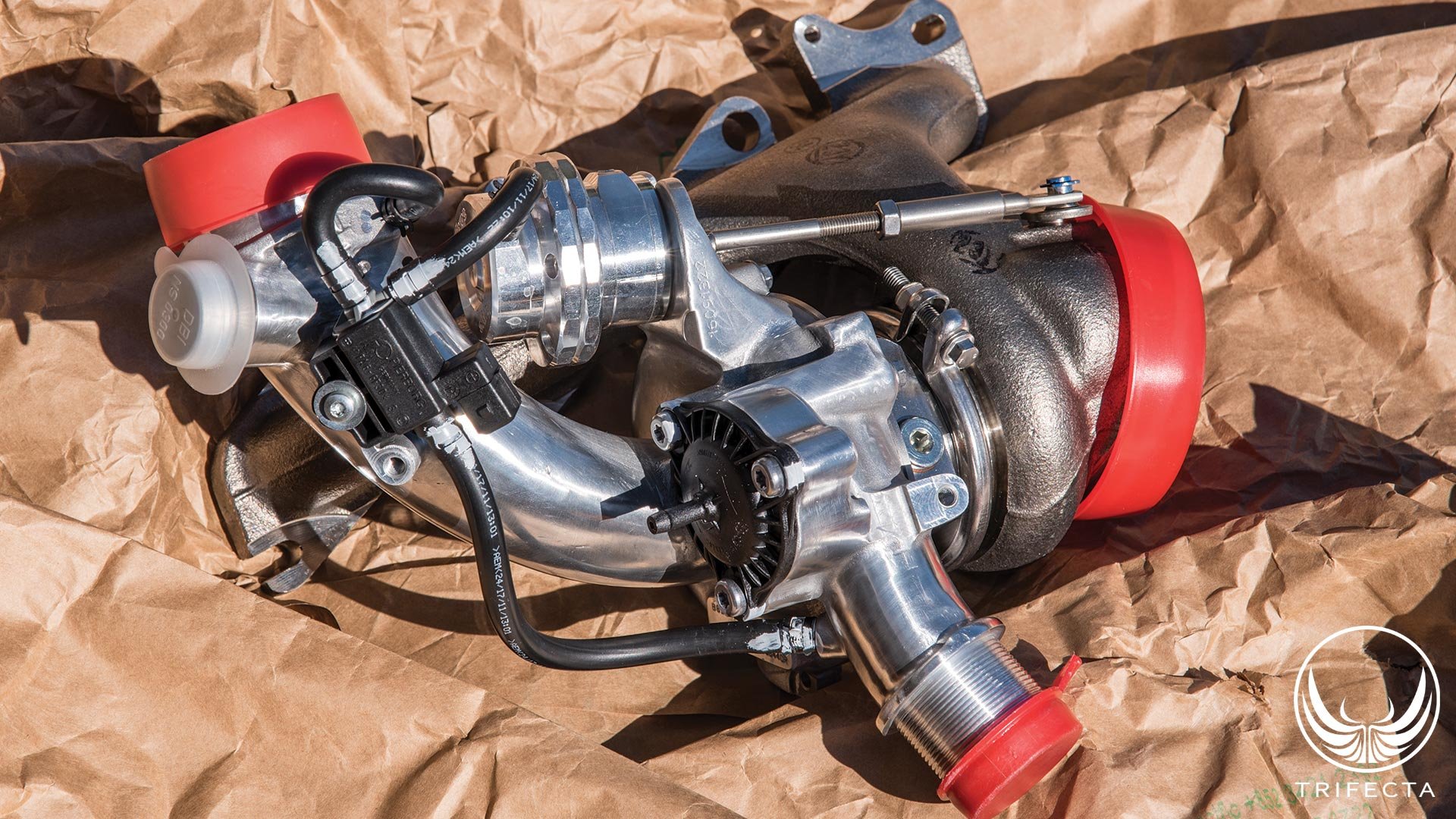

We started with a 2017 Chevrolet Cruze hatch. We took the original engine and transmission out, and swapped in an engine and transmission from a 2017 Chevrolet Malibu Premier. This is the 2.0L turbocharged engine coupled with the 9T50 front wheel drive 9 speed automatic transmission. With proper calibration work, this engine and transmission in its stock form can deliver about 300HP at the flywheel. This equates to around 240HP at the wheels, which is about 70WHP more than the LE2 can produce with a proper tune. We didn't stop there, though. We also installed aftermarket cams to increase airflow and fuel pump supply. And we added our "T40" turbocharger, which produced darn near 400HP when we tested on a Chevrolet Malibu recently. We have an aftermarket front mount intercooler for tuned up 2.0T engines, a cold air intake, and a custom dual-outlet exhaust system. The challenges were many in building this car. Which axles to use? Which mounts? Where to move the radiator to make room for the turbocharger? The wiring! The engine may fit in this car like it was designed for it, but there couldn't be much more different with the wiring harness on the Cruze vs the Malibu. But, in the end, it all works, as if Chevrolet themselves built the car. You push the start button and the engine roars to life through the custom exhaust system with an aggressive yet tasteful note. It may seem like the little things, but it's the little things that matter: The gauges work. The heater works. The brakes work. Shift it into Drive, and you're off. The 9sp automatic transmission peels through the gears smoothly. Put the pedal down, and hold on. The car is a work in progress, there's still a few things that need to be done with it (like fabbing a bracket for the ECM instead of using zip ties lol), but make no mistake, the Cruze has entered a new age.

-

-

It's common knowledge that the Corvette, going back to the mid 2000s has offered an exhaust valve option (RPO: NPP). In 2014, when the Chevrolet Corvette Stingray (C7) arrived, it included dual mode exhaust valves as standard equipment, as well as a set of "AFM exhaust valves" to help reduce the odd exhaust notes when the engine runs in 4 cylinder mode. When the 6th Gen Chevrolet Camaro came along, the dual mode exhaust valves became standard equipment on the SS and ZL1, and optional equipment on the V6. These exhaust valves are designed to stay closed during normal driving operation to meet federal noise standards, and essentially bypass the mufflers under hard acceleration for maximum performance. In Track mode, on the C7, the valves are designed to stay open all the time. The exhaust valves are controlled by the same ECU that controls the fuel pump pressure on the Chevrolet Cruze and Chevrolet Sonic. In fact, we found that the Camaro SS CCM is connector-compatible with the Cruze CCM! With a bit of wiring, and some software work in the CCM, retro-fitting exhaust valves on the Cruze / Sonic might be possible. Of course, the question is, how would one set up the exhaust valve? One idea we have is to T the single exhaust near the rear of the car into two pipes, one going through a standard muffler, and the other, through an exhaust valve, to a straight pipe out the back (or a cut out). Just one of the innovative projects TRIFECTA has on the horizon for 2018!

-

Old School Fuel Injectors Ironically, the relatively modern LUJ/LUV uses the relatively old-school “EV1” style fuel injector connector. As such, aftermarket fuel injector choices are somewhat limited unless costly harness adapters are used. Bosch “Green Giants” 42# Fuel Injectors These fuel injectors have been popular in the aftermarket for some time. This a very good, general purpose fuel injector for the 1.4T engine, because they're not so large that they cause injector misfire or over fueling problems at idle. They are available with an “EV1” style connector, so harness adapters are not necessary. They are large enough to support full E85 on the stock turbo, and mild turbo upgrades (e.g. compressor wheel upgraded units). However, there are three problems with them: Fakes / non authentic replicas: When we first started testing these injectors back in the 2011-2012 time frame, the first set we received worked fantastic. Then, our supplier sent us a new set which were “much cheaper”. Despite looking the same, these did not work well, at all. The engine had misfire problems at idle. Upon investigation, we determined that this second “cheaper” set of fuel injectors was in fact a replica and was built using very poor manufacturing tolerances. Price: Why are there replicas / knock offs? The answer is simple: the authentic units are expensive! As of this writing, authentic “green giants” cost anywhere from $200-$250, retail, for a set of 4. Availability: For reasons not yet determined, the availability of the “green giants” has diminished as of late. Most retailers have them back ordered. Bosch 52# Fuel Injectors As of more recently, the Bosch 52# fuel injector has become an option for the 1.4T. They share most of the same benefits that the “green giant” does, however, there are two problems with these fuel injectors: Not “EV1” connector: This one's simple. They won't directly plug in to the engine harness of the 1.4T. As such, to use these, you need to add bulky, costly harness adapters. Price: Looking around at various retailers, a set of these injectors, with the required harness adapters will run you anywhere from $250 - $300 for a set of four. Siemens-Deka 60# (SD-60) Fuel Injectors You can throw a stone and hit five gear heads that know what these injectors are. They were one of the first widely-available “EV1” style aftermarket fuel injector upgrades for the LS1 engine dating back to the end of the last century. These fuel injectors are high performance with enough fuel flow to solve the fueling problems of almost any streetable high performance build. They are readily available, being very easy to source. They are also one of the lowest cost high performance aftermarket fuel injector available, with a set of four pricing in at $150-$200. Because they are available in the “EV1” style connector, they can be used on the 1.4T without harness adapters. If they could be used on the 1.4T, they'd be the perfect choice. However, they are also notoriously finicky in some regards, and based on our early research, were ruled out as feasible. That's changed now, though. First, a discussion about the problems with them. Curse of the SD-60s One of the issues that's plagued tuners since the SD-60s became available is their short pulse width operation. The larger (higher flowing) a fuel injector is, the more fuel it moves for a given amount of “open” time (pulse width). Also, the larger a fuel injector is, the more difficult it is to control at extremely short pulse widths, because the internal parts are larger, and therefore, heavier. If a fuel injector is operated at too short a pulse width, the injector can “misfire”. The ECU tries to open and close the injector so fast, it cannot do so reliably. When it fails to open and close, no fuel is injected, and the cylinder misfires. These two issues confluence to make idle operation with SD-60s extremely problematic and challenging. On larger engines, like the LS1, for instance, which displaces .7125L / cylinder, the SD-60s are relatively close to providing the correct amount of fuel for idle operation. However, on smaller engines, like the 2.0L SC MPFI (LSJ) – which displaces .5L / cylinder – the SD-60s cannot run at a short enough pulse width for proper fueling. So a tuner is left with making a choice between two not-so-good scenarios. Either they can live with the injector misfiring at idle, or they live with pinning down the minimum injector pulse width to avoid misfiring, but which causes the idle mixture to be too rich. The 1.4T is EVEN SMALLER, clocking in at .35L / cylinder. In other words its fuel demand per cylinder is roughly HALF of the LS1 engine. This means the problems seen on the 2.0L are even worse. We figured this out back in 2011-2012 and quickly eliminated the SD-60s as a viable choice for the 1.4T at the time. However, we recently revisited it, and now we think it's the best choice. Here's why... The LUJ/LUV Chassis Control Module Did you know that your Gen 1 Cruze / Gamma II has a variable speed fuel pump? It's true. And it's controlled by a discrete ECU called the Chassis Control Module (CCM). The CCM receives messages from the Engine Control Module (ECM) that dictate what the fuel pressure supplied to the injector rail should be. Why? The answer is that because these vehicles are both MPFI and turbocharged, the fuel pressure supplied to the injector rail needs to be varied based on how much boost there is in the intake manifold. The factory calibration varies the pressure between 300kPa (43.5 psi) and 400kPa (58psi) depending on the operating conditions. In our earlier research, we experimented with SD-60s and a lowered commanded fuel pressure in the ECM calibration. However, at the time, the CCM would not honor requests from the ECM to run the pump at a pressure level that was low enough to work with the SD-60s. Less is More More recently, however, we decided to look into whether we could change the CCM's calibration to honor requests from the ECM to run the fuel pressure at a level that was low enough to support the SD-60s. Here's the deal: Yes, the SD-60s flow way too much fuel (at idle) for the 1.4T – but that's at 43.5psi. If you lower the fuel pressure, the flow rate goes down. And as a result, the pulse width can be increased. With a specific CCM calibration, matched with an ECM calibration, we found we were able to run the SD-60s on the 1.4T with NO problems. No injector misfire. No rich idle. In fact, our engineers thought the 1.4T idled SMOOTHER with the SD-60s than even the stock injectors, or the “green giants”! SD-60s are Looking Like the Best Option The ECM/CCM is simply a reflash (software update) for the vehicle. If you're switching injectors, you're going to be flashing the ECM anyway. We always thought if the SD-60s could be made to work, they'd be the best fuel injector for the 1.4T. They're the cheapest and easily available. With TRIFECTA's ECM/CCM calibration, now the SD-60s are a real option for 1.4T tuners!

-

An HSN** means that the part was installed and tested for correct functionality on a TRIFECTA development vehicle, with the TRIFECTA calibration product, and if any specific calibration changes are necessary to support or optimize it, these changes have been established and finalized. As such, customers wishing to install this part on their vehicle may do so under the Advantage line product and will not require any customization beyond, in some cases, a parts-specific calibration update. The following is the manufacturer's description of the product: “The K&N 63-3097 AirCharger air intake system replaces the restrictive factory air filter and air intake housing on specific Chevrolet Malibu models. K&N air intakes are designed to dramatically reduce air intake restriction as well as smooth and straighten air flow. This allows your engine to inhale a larger amount of air than the factory air filter assembly. More air means more usable power and acceleration throughout the engine’s RPM range. The air intake comes with a chrome topped K&N high-flow air filter and a heat shield that installs into the original air box space. Air is directed through an aerodynamically engineered intake tube into the engine’s turbo inlet for a guaranteed power gain. The tube accommodates the factory mass air sensor and crank case vent hose. The oversized cone shaped air filter can be used for up to 100,000 miles before servicing is needed depending on driving conditions. This air intake is relatively easy to install, usually in 90 minutes or less using your vehicle’s existing factory mounting points. This air intake system can be installed easily with common tools.” (For full info, please see the manufacturer's website here: https://www.knfilters.com/mobile/mProduct.aspx?prod=63-3097) In general, our hardware team found the unit to be easy to install, and easily reversible for dealership visits. It increases “intake noise”, so turbocharger “whine” and “bypass” events are more easily heard. The serviceable filter element reduces long term air filter element replacement costs. Future or existing TRIFECTA customers interested in purchasing this product may be able to do so through TRIFECTA, please contact our support team for more info! **Please note: A Hardware Support Notification (HSN) from TRIFECTA is merely a statement that we tested the product with our calibration products, and in some cases may include performance data collected and/or ad-hoc comments on the product by TRIFECTA. TRIFECTA is not specifically affiliated with, nor specifically endorses (or is endorsed) by the product listed in this HSN. TRIFECTA makes no warranty or claims regarding the quality or performance of the product listed in an HSN. In some cases, TRIFECTA may act as a reseller of hardware described in an HSN and as such may receive a profit by reselling said hardware. TRIFECTA always recommends that hardware be installed by an experienced and certified shop or facility. Unless otherwise specified, customers purchasing hardware from TRIFECTA would need to work directly with the manufacturer in the event there is a question regarding installation. Unless otherwise specified, all hardware available through TRIFECTA will “drop ship” from either the manufacturer, or a distributor.

-

TRIFECTA presents: Cadillac ATS-V MY2016+ Performance Calibration

TRIFECTA Performance commented on TRIFECTA Performance's article in News

The calibration can be installed at home with a Windows 10 laptop*, within 20 minutes. You can essentially go from 464hp to 600hp without turning a wrench, in 20 minutes. We have technical support staff standing by should you need any assistance as well. *(or a Mac running Windows via emulation software or dual-boot) -

More boost for your turbo Equinox While the all-new Chevrolet Equinox 2.0T performs well out of the box, the TRIFECTA recalibration result is nothing short of amazing. The new 9 speed automatic transmission is geared to take full advantage of the power curve of the LTG engine, and with an extra 50 horsepower at the wheels on tap, with TRIFECTA, the Equinox turns into a tire shredding machine. FUN FACT: The engineering team that developed the all-new Equinox product had just wrapped up the Cadillac ATS-V tuning program. Despite just working with a 600HP Cadillac, by the time they were done with the Equinox, they were giggling everytime they took off from a stop with a heavy pedal! 2.0L Turbo LTG dyno (on 91 octane pump gas) (this vehicle is a 2018 Chevrolet Equinox with the 2.0L Turbo LTG engine) - stock wheels/tires Instilling sport in the Equinox's DNA Raw power is great, but how that power is delivered is almost more important. When you're dealing with a transmission that has so many gears, purposeful, intelligent, and confident shifting is critical, as is pedal response. TRIFECTA's driveability engineers worked tirelessly to instill a sporty driving character without making the vehicle feel busy-shifting, laggy, or twitchy. Milder manners, when needed We also understand there may be times when a milder persona is desired. As is found on most of GM's most expensive vehicles, with TRIFECTA, you can switch back to a more docile pedal response and transmission shifting, on the fly, with TRIFECTA's exclusive Driver Selectable Vehicle Modes ("DSVM") feature, using the cruise control button. A show of hands, how many in this room want to be able to disable "auto stop"? "Auto stop", "start stop", or whatever you want to call it, you know what we're talking about. It's when the engine shuts off entirely (and sometimes disconcertingly) when the vehicle comes to a stop. Its meant to help with fuel economy, but in many cases its more of an annoyance, than anything. Some vehicles have a discrete button to disuade the vehicle from auto stopping, but the all-new Equinox is not one of them. With TRIFECTA's exclusive Performance Auto Stop Mode ("PASM"), now you, too, can say to your Equinox, "No sir, I don't want auto stop right now." No, we won't give you a button to tape to the console for this. PASM, like DSVM, is also controlled by the cruise control button. Calibration customization, for those who need it Need support for a wicked dual-snorkel cold air intake kit? With TRIFECTA's Elite calibration tier, customized calibration support is available** for modifications which are not compatible with the factory calibration. ** Support for modifications is subject to specific terms and conditions TRIFECTA MY2018+ Chevrolet Equinox Performance Calibration Key Features: - Specific power gains of up to +48 ft-lbs of torque, +49 horsepower measured at the wheels - Dramatically improved drivability characteristics for everyday driving maneuvers - Exclusive Driver Selectable Vehicle Modes ("DSVM") for switching performance profiles on-the-fly - Exclusive Performance Auto Stop Mode ("PASM") for disabling Auto Stop when in Sport mode - Installs in about 20 minutes - Flash back to stock functionality included For more info, see here: https://www.trifectaperformance.com/store/product/2401-2018-chevrolet-equinox-20l-turbo-advantage/

-

At this preliminary stage, we've installed the K&N Intake system on our test fleet, and have begun assessing for initial vehicle performance, quality, driveability, obvious issues, etc. So far, we've amassed a good number of miles and have not had any issues with it when paired with the TRIFECTA calibration. This intake is designed for a stock vehicle, running the stock calibration, so we do not foresee any issues using it with the TRIFECTA calibration, but as the airflow dynamics with our calibration are different than the factory calibration, it would be responsible to fully test the intake system with our calibration over a longer period of time, under different environmental conditions, while collecting performance data. We will release additional support notices as we collect additional data for this and other aftermarket modifications.

-

With roughly 20 minutes to spare, you can reprogram your Cadillac ATS-V to drive and perform even better than it did from the factory. Without changing a single piece of hardware, you can bring your 464HP sport sedan or coupe up to 600HP** (380HP up to 500HP as measured at the wheels on a chassis dyno), and give it a more sport-inspired drive feel. (** Estimated crankshaft horsepower based on calculated drivetrain losses) If you have a 2017 or newer Cadillac ATS-V with an automatic transmission, you do NOT have to remove your transmission control module (“TCM”, T87A) for any unlocking process. All TRIFECTA Cadillac ATS-V calibrations include extensive transmission strategy reworking. (2016 models use the "T87" controller, which also does not require removal from the vehicle) Why TRIFECTA? Why buy a tune from a dyno shop that might run your car on the rollers 10 times when you can buy from a company that's channeled over several hundred dyno pulls' worth of testing into their product? Rather than relying on a “dyno tuner” that may or may not have experience tuning the ATS-V (but almost certainly to their local area only), with TRIFECTA you can rest assured you're purchasing from the company that's been in the GM factory turbo vehicle tuning business longer than anybody else, in many cases pioneering the tuning aftermarket for these vehicles. The TRIFECTA ATS-V calibration has been subjected to over 300 chassis dyno pulls, on dynos across multiple continents, and tens of thousands of test miles have been accumulated in virtually every climate, elevation and season. TRIFECTA's calibration for the Cadillac ATS-V is also packed full of exclusive and innovative features to make your ATS-V experience even better. From reworked knock control logic and zoning, to active fuel rail pressure management, to adding full-boost launch control, TRIFECTA's engineering team delivers exclusive features that Cadillac didn't even consider. Key Features of the TRIFECTA Performance MY2016--2017+ Cadillac ATS-V powertrain calibration software reprogramming: Dyno-proven gains in power Using industry standard chassis dynamometers, TRIFECTA shows proven gains in torque and horsepower for your Cadillac ATS-V, using only the factory hardware: Telemetry-proven gains in acceleration Dyno sheets are great, but they only show power output. Using professional grade telemetry equipment, TRIFECTA has also established proven gains of up to 0.87 seconds in 0-60MPH acceleration profiles versus the factory calibration.** **traction limited by factory tire and pavement condition (generally dry, medium worn asphalt). Faster times achievable with R-compound tires on prepared surface. TRIFECTA Exclusive ATS-V Calibration Features TRIFECTA's Cadillac ATS-V calibration includes many features that are both desired, and exclusive to TRIFECTA's calibration: Standard Tour Mode (STM) The ATS-V offers several different drive modes from the factory such as Tour, Sport, Track and Winter / Snow / Ice modes. TRIFECTA's custom operating system modifications allow us to optionally (but included by default) offer Tour mode which limits horsepower and torque output to levels very similar to the factory levels. This feature is very useful if the vehicle is driven by others who would prefer the vehicle to operate like it does from the factory. Drive modes can be changed on the fly, and as such, the driver may select any mode, at any time. No transmission control module (TCM) “unlock” required General Motors, starting in the 2017 model year, began using a new transmission control module (“TCM”, called the T87A) for the 8 speed automatic transmission used in the Cadillac ATS-V. The T87A employs digitally signed programming segments to prevent transmission calibration reprogramming by parties other than General Motors. While there is an exploit to unlock the T87A to allow reprogramming by other parties, it requires physical access to the TCM (via removal from the vehicle), and an unlock procedure. However, TRIFECTA is pleased to announce this “hands-on” exploit is not needed for the TRIFECTA Cadillac ATS-V calibration product. Extensive transmission strategy reworking is accomplished without “unlocking” the T87A. (2016 models use the "T87" controller, which also does not require removal from the vehicle) Active Rail Pressure Management (ARPM) Worried about DI (direct injection) rail pressure when turning up your boost? TRIFECTA's Active Rail Pressure Management (ARPM) engine control module (ECM) operating system customization allows higher boost levels to be achieved while actively monitoring the DI fuel rail pressure and reducing boost, if a drop in rail pressure is predicted, based on past and present operating conditions. To read more detail about ARPM, see our article: TRIFECTA: Active Rail Pressure Management TRIFECTA Full-Boost Launch Control (8-Speed Auto) Anybody who's tried to launch the automatic transmission Cadillac ATS-V has noticed it's near impossible to both hold the rear wheels from spinning and simultaneously build full boost at launch. TRIFECTA's Full-Boost Launch Control exclusive feature allows the application of the brake, and full accelerator to build up to 18psi of boost while keeping the tires from spinning. After releasing the brake, full power is instantly applied. While this is helpful for little more than a smoke show on the stock tires, with proper tires and track surface, much quicker launches can be achieved (this feature does not interfere with the factory launch control features, and these features continue to work as they did from the factory). TRIFECTA Bi-directional Enhanced Knock Control and Zoning Whether anybody wants to believe it, or not, “knock”, defined as noise detected by the knock sensors, is going to occur from time to time. Generally this occurs when there's a transient change in fuel quality, or operating conditions. While the factory's knock control constructs are advanced, they make certain assumptions about how, and in which direction to adjust knock factor when knock is detected. The factory knock control strategy on the Cadillac ATS-V uses one zone only, encompassing the entire RPM range, and engine load range. TRIFECTA's Cadillac ATS-V calibration utilizes six zones and allows for finer self-adjustment when dynamic timing adjustments are needed. Furthermore, TRIFECTA's enhanced knock control employs an “ongoing” strategy which retains learned knock factors even after the engine is shut down, and continues to use them the next time the engine is started. Bi-directional knock control allows the ECM to begin its knock adaptation in the middle of the timing adjustment map, rather than always assuming it's running “high octane” fuel and potentially exposing the engine to audible knock. Enhanced Engine and Transmission Response Let's face it, Cadillac did a good job making the Cadillac ATS-V fun to drive from the factory. That didn't stop our drivability engineers from making it even better. In Sport and Track modes, accelerator pedal response is improved, while also refining tip-in response. Transmission downshifts are progressive, as opposed to the “all or none” strategy the factory generally goes with. Lower gears are held to a higher RPM, so a downshift is not needed if the driver decides at the last moment to chase down and humiliate a European Exotic. Tour mode and Winter / Snow / Ice modes retain stock pedal response and transmission shift patterns. Support for Aftermarket Parts TRIFECTA was one of the first companies to bring the concept of comprehensive remote tuning to the mass market. If you have aftermarket parts, talk to us about adapting our calibration to support them! Specifications of the TRIFECTA Performance MY2016--2017+ Cadillac ATS-V 3.6L Twin Turbo (LF4) ECM software reprogramming: Gains of up to +111 ft-lbs and +121 WHP under the curve (and +73 ft-lbs and +114 WHP peak on 91 octane) Powertrain calibration has been tested and validated for various environments, such as cold/heat, elevation, and variations in fuel quality Power feels linear and immediately responsive (improved drivability and throttle attentiveness) Retains all GM OE diagnostics and ECM functionality Retains all OE error code reporting and functionality Emissions readiness checks are present; emissions compliant Maintains functionality of ABS and TC systems Knock detection mechanisms and OE engine knock detection sensitivity is retained The TRIFECTA flash loader and Transparency featureset does not increment the ECM write counter or increment entries in the flash history Return to stock functionality included with flash loader TRIFECTA Octane Adaptive MKIII featureset will bias for lower octane fuels (multi dimensional airflow knock zoning and timing decay tables, not just high/low) Specifications of the TRIFECTA Performance MY2016--2017+ Cadillac ATS-V 8L90 8-Speed automatic transmission TCM calibration software reprogramming: Supplementary 8L90 transmission TCM reprogramming compliments the ECM reprogramming and completes the TRIFECTA Powertrain Calibration: designed to work in unison with the ECM reprogramming for optimized performance Improved shift times in adverse shift patterns Improved shift logic (improved drivability) Does not shorten transmission life or increase cooling requirements Retains all OE diagnostics and TCM functionality Retains all OE error code reporting and functionality Improved fuel economy with improvements made to torque converter slip profiles Installation Notes: Estimated installation time of ~20 minutes Premium fuel is recommended Additional information and availability: This powertrain calibration includes a TRIFECTA powertrain calibration file specific to your vehicle and includes a flash loader device Advertised gains are quoted as 'up to' and may be less for a vehicle operated at altitudes higher than near sea level. View this product in our store: 2016+ Cadillac ATS-V - 3.6L Twin Turbo

-

2016+ Cruze 1.4T (LE2) October 2017 Calibration Update

TRIFECTA Performance posted a article in News

Why the update? Some of you have provided valuable feedback regarding the drivability of our current-generation product, which we have taken into careful consideration. What is changing? This update is a drivability update specific to vehicles with an automatic transmission, which does the following: "Sport+" mode replaces "Sport" mode: Sport+ mode is an evolution of the original Sport mode which broadens the "tip-in" range in the accelerator pedal. Sport+ mode also introduces the same progressive shifting algorithm we've incorporated into vehicles with the 8, 9, and 10 speed automatic transmissions without sacrificing mid-pedal sensitivity for a more well-balanced, sporty feel! "Standard" mode replaces "Stock" mode: In transitioning from our Sport mode to Stock mode, many feel the Stock mode is much too conservative on take-off. Our original goal was to retain the stock pedal and transmission response as accurately as possible in stock mode, but the challenge is the difference is too great between Sport (and now Sport+) and Stock mode. Many customers requested that we provide a mode that's improved over stock, but still retains a more relaxed driving style. With Sport+ and Standard mode, take-off dynamics are very similar, and the transition is much smoother, especially with TRIFECTA's exclusive Performance Auto Stop Mode (selectable auto-stop enable). Are there any changes in performance / power output? This update retains the same power envelope as our current-generation TRIFECTA calibration, and is a pedal-response and transmission strategy (drivability) update only. How do I receive the update? All existing Gen II Cruze customers with automatic transmissions have already been notified by email, and their calibrations updated in their downloads. All that is necessary is to download and install the update. New customers will receive the update as our standard offering. If you have any questions, or require any assistance, please don't hesitate to email us at info@trifectaperformance.com or use the Contact Us form at trifectaperformance.com. In the mean time, stay tuned to us here at http://www.trifectaperformance.comand Facebook for the latest information from TRIFECTA! Thank you - TRIFECTA Performance View this product in our store: 2016--2018+ Chevrolet Cruze / Cruze Hatch - 1.4L Turbo Read more about TRIFECTA's Support for the Gen II 1.4T LE2 Cruze: TRIFECTA: More power, more fun for your 2016+ Chevrolet Cruze 1.4L Turbo (LE2) TRIFECTA: Making Auto Stop more performance oriented. Meet Performance Auto Stop Mode. TRIFECTA: Baseline dyno testing of the 2016 Chevrolet Cruze RS 1.4 Turbo (RPO LE2) TRIFECTA: 1.4L Turbo Throttle Body Comparison LE2 to LUJ/LUV TRIFECTA: Meet the GM LE2 Engine -

-

In about 20 minutes, you can increase the performance, power, sport factor, and economy for your 2017+ Chevrolet Colorado / 2017+ GMC Canyon. The TRIFECTA Advantage Powertrain Calibration for the MY2017+ Chevrolet Colorado is intended for stock vehicles, and includes a TRIFECTA flash loader The TRIFECTA Advantage+ Powertrain Calibration for the MY2017+ Chevrolet Colorado allows speedometer recalibration for aftermarket wheels and tires (among other certain calibration adjustments), and includes a TRIFECTA flash loader The TRIFECTA Elite Powertrain Calibration with Individualization (Custom Profiling) for the MY2017+ Chevrolet Colorado / GMC Canyon LGZ includes calibration individualization, remote diagnostics, and comprehensive aftermarket hardware software integration support. (Includes a TRIFECTA flash loader) Key Features of the TRIFECTA Performance MY2017+ Chevrolet Colorado / GMC Canyon powertrain calibration software reprogramming: While on the outside, the 2017+ trucks look the same (save for a red V6 on the tailgate), underneath the hood, its a totally new truck. Sporting an application-specific 3.6L V6 of the new HFV6 generation (read more about the differences here: TRIFECTA: We love the Colorado/Canyon. We love the 2017 model even more.) and 8 speed automatic transmission, our engineers had to start from scratch in building the successor to the already best-in-class product for the 2015-2016 Chevrolet Colorado / GMC Canyon. Dyno-proven gains in power Using a chassis dynamometer, TRIFECTA has established proven gains in torque and horsepower! https://vimeo.com/207718866 3.6L LGZ dyno graph(on 91 octane pump gas) (this vehicle is a 2017 GMC Canyon CrewCab 2LT with a 3.6L LGZ engine) - stock wheels/tires: Telemetry-proven gains in acceleration Using professional grade industry-standard telemetry equipment, TRIFECTA has also established proven gains of up to .5 seconds in 0-60MPH acceleration times versus the factory calibration through power gains, throttle ramp rates, and shift schedule optimization. Driver Selectable Vehicle Modes (also known as “DSVM” or “Shift-on-the-fly”): The ability to change the driving behavior of a truck has always been of great interest to the truck community. TRIFECTA exclusively offers the ability to change between three driving modes, on the fly. Three profiles offered: Sport, Eco, and Tow/Haul Sport mode offers aggressive pedal response, more progressive downshifts, extended shift points (selected when cruise control system is disarmed) Eco mode offers economy-centric pedal response and shift points (selected when cruise control system is armed) Tow/Haul offers the factory tow/haul mode (selected when tow/haul button is pressed / mode engaged) Accelerator Pedal Detent Delete (Sport Mode): The LGZ-equipped vehicles, along with most other trucks equipped with an 8 speed automatic transmission have a “detent” at the bottom of the accelerator pedal travel. On the factory calibration, the driver must consciously press through this detent in order to achieve maximum acceleration and full downshifting. While in TRIFECTA's SPORT mode, maximum acceleration and full downshifting can be achieved without passing the detent. This allows for a level of throttle modulation during sporty driving maneuvers not possible on the factory calibration. TRIFECTA Performance Active Fuel Management (PAFM) (Advantage+ or Elite package) The LGZ offers V6/V4 mode. GM has succeeded in making V6/V4 transitions (AFM, or Active Fuel Management as GM calls it) extremely smooth, such that in most cases they can't be noticed. However, some customers may have exhaust or other modifications that cause the truck to produce an undesirable exhaust note while in V4 mode. TRIFECTA exclusively offers three options with regard to adjusting AFM parameters with this product: AFM available/active in all drive modes (default) AFM disabled in Sport mode AFM disabled entirely Advantage+ and Elite customers may request AFM behavior changes when ordering their product. Optimum shifting improvements for your transmission – without “unlocking” the TCM The LGZ equipped vehicles come mated to an 8 speed automatic transmission (8L45). A TRIFECTA exclusive-feature allows recalibration of the transmission's behaviors WITHOUT requiring an expensive, and inconvenient “unlocking” service. Specifications of the TRIFECTA Performance Chevrolet Colorado MY2017+ and GMC Canyon MY2017+ 3.6L LGZ ECM software reprogramming: Gains of up to +41 ft-lbs and +28 WHP under the curve (and +18 ft-lbs and +10 WHP peak on 91 octane) Powertrain calibration has been tested and validated for various environments, such as cold/heat, elevation, and variations in fuel quality Power feels linear and immediately responsive (improved drivability and throttle attentiveness) Retains all GM OE diagnostics and ECM functionality Retains all OE error code reporting and functionality Emissions readiness checks are present; emissions compliant Maintains functionality of ABS and TC systems Knock detection mechanisms and OE engine knock detection sensitivity is retained The TRIFECTA flash loader and Transparency featureset does not increment the ECM write counter or increment entries in the flash history Return to stock functionality included with flash loader TRIFECTA Octane Adaptive MKIII featureset will bias for lower octane fuels (multi dimensional airflow knock zoning and timing decay tables, not just high/low) Specifications of the TRIFECTA Performance MY2017+ Chevrolet Colorado / GMC Canyon 8L45 8-Speed automatic transmission TCM calibration software reprogramming: Supplementary 8L45 transmission TCM reprogramming compliments the ECM reprogramming and completes the TRIFECTA Powertrain Calibration: designed to work in unison with the ECM reprogramming for optimized performance Improved shift times in adverse shift patterns Improved shift logic (improved drivability) Does not shorten transmission life or increase cooling requirements Retains all OE diagnostics and TCM functionality Retains all OE error code reporting and functionality Improved fuel economy with improvements made to torque converter slip profiles Installation Notes: Estimated installation time of ~20 minutes Premium fuel is recommended, but not required Additional information and availability: Powertrain calibrations currently exist for North American vehicles only, with more regions to follow This powertrain calibration includes a TRIFECTA powertrain calibration file specific to your vehicle and includes a flash loader device View this product in our store! Chevrolet Colorado GMC Canyon

-

TRIFECTA's Active Rail Pressure Management Introduction – Direct Injection Over the last 10 years, General Motors (GM) has been converting all of their engines to use what they call SIDI (Spark Ignited Direct Injection), oft referred to as just DI (Direct Injection). DI promises improved fuel economy, improved engine power and lower vehicle emissions versus the traditional MPFI (Multi Point Fuel Injection) that has been in use since the late 1980s on General Motors vehicles. However, DI equipped engines present unique challenges for those wishing to modify and increase the power output of their vehicles while maintaining proper operation. TRIFECTA is a leading manufacturer of aftermarket calibrations (tuning) for DI engines and has consistently been the pioneer of technologies that allow greater power output from DI based vehicles. One of those technologies is called Active Rail Pressure Management. To understand why it's a critical part of calibration work when working outside the design specifications of a DI engine, let's first dig into how DI works. Direct Injection – how does it work? Since the introduction of DI on the 2007 Pontiac Solstice GXP and 2007 Saturn Sky Redline, GM's implementation of DI has generally followed the same architecture. DI fuel systems work very similarly to diesel direct-injection systems in that the fuel injector, which provides fuel for combustion, is located in the cylinder head and feeds the fuel pulse directly into the combustion chamber for a given cylinder. This is in contrast to MPFI systems which use a fuel injector (for each cylinder) typically located in the intake manifold, just prior to the intake valve. On a simple level, DI systems utilize the following components: 1. Fuel tank (fuel storage) and fuel filter 2. Low pressure fuel pump and pressure regulator (generally 40-70psi) 3. High pressure fuel pump and pressure regulator (up to 3000psi) 4. DI fuel rail and DI fuel injector (one per cylinder) Fuel stored in the tank is pressurized to a low pressure, and provides the fuel to the high pressure pump. The high pressure pump raises the fuel pressure and delivers it to the DI fuel rail, and ultimately, the DI fuel injector. The low pressure pump is the same type that's used in typical MPFI systems. It's an electric pump and uses a closed-loop pressure control system, with a discrete ECU (either a chassis control module, or a fuel pump control module) to manage the low pressure side pressure and flow rate. The high pressure pump is a mechanical pump, which, much like in a diesel engine, is driven mechanically. Diesel engine pumps may use a variety of drive mechanisms, but the gasoline DI engines use a camshaft as the drive mechanism. Pressure (and, in later models, fuel temperature) is monitored by the ECM (engine control module), and the pressure is controlled by the ECM as well. Fuel injector timing and pulsewidth is calculated in part by the ECM's calibration, and in part by the immediate fuel demands of the engine. All of these inputs and outputs are calculated thousands of times per second to ensure precise fuel delivery. Fuel injector flow rate, low pressure pump, and high pressure pump capacities are carefully calculated by GM engineers to provide adequate fueling (within certain operational margins) under all operating conditions. However, the aftermarket is focused specifically on increasing the power output beyond factory specifications. DI can pose unique challenges in this regard. (2.0T LNF ECM, Fuel Rail, High Pressure Fuel Pump - Source: GM Media) Concerns with raising fuel demands of the DI engine On MPFI equipped vehicles, addressing increased fuel demands (due to increasing supercharger or turbocharger boost levels, utilization of ethanol blends of fuel, utilization of “richer” fuel mixtures, and/or adding forced induction) was largely centered around ensuring the low pressure pump can provide adequate fuel volume and that the fuel injectors themselves could provide this increased fuel volume quickly enough. Fueling an engine using DI, however, poses some unique challenges compared to MPFI, the two largest being: 1. DI systems, due to their design have a much smaller “window” of time during which fuel can be injected optimally. 2. Partly due to #1, and also because the fuel pressure must be higher than the combustion chamber pressures, DI systems must operate at relatively high pressures vs MPFI systems which must only overcome the intake manifold pressures. It's not enough on a DI engine to just increase the fuel injector size, and the volume of fuel that can be provided by the low pressure pump like it is with an MPFI system, and in many cases, neither of these are the first limiting factor DI engines with power adders run into. Quite often, the high pressure pump's ability to provide sufficient fuel volume at sufficient pressure becomes the limiting factor. This is why the aftermarket tuners are so concerned with “fuel rail pressure” levels (e.g. the pressure of the fuel in the rail just prior to the fuel injector under high loads). Modifications, whether they be software, or hardware (or both), which cause the fuel rail pressure to fall short can lead to fueling errors (both fuel quantity and injection timing events), which can lead to possible engine destruction. Engine destruction is actually rare, though, because improper fuel rail pressure generally causes the engine to run at drastically reduced power levels. The design of DI is inherently self-limiting this way. (2.0T LTG Low Pressure Fuel Pump) The relationship of injection timing, fuel pulse width and fuel rail pressure With GM's DI implementation, an injection event begins with two basic calibrated parameters – the desired fuel rail pressure, and the DESIRED start of injection angle (relative to the piston's position in the cylinder, in degrees). The ECM references certain tables in its calibration and then commands the high pressure pump to provide a DESIRED rail pressure for the specific operating conditions at the time. Next, the ECM first determines the immediate fuel demand. This is largely a dynamic factor of the amount of air entering the cylinder, and the commanded air to fuel ratio. Once the ECM calculates the required fuel volume, it checks the ACTUAL rail pressure (which should be the same as the DESIRED rail pressure) to calculate how long the injector needs to be opened for (the injector pulse width) to provide the required fuel volume. Finally, the ECM determines when to open the injector (ACTUAL start of injection angle). In a perfect world, again, this would be the same as the DESIRED start of injection angle. (3.6L LFX High Pressure Fuel Pump) Dynamic compensation of fuel injection start angle Unfortunately, it's not always a perfect world. Here's a list of certain scenarios where the ACTUAL start of injection angle may not be the same as DESIRED: 1. The engine's fuel demands are higher (due to increased airflow, a richer fuel mixture, and/or variances in operating conditions) than they were at the time the rail pressure and injection timing tables were calibrated originally. 2. The ACTUAL fuel rail pressure is less than the DESIRED fuel rail pressure. 3. The commanded ignition timing (spark advance) is more advanced than it was when the rail pressure and injection timing tables were calibrated originally. 4. There's been a malfunction of the fuel control system (mechanical or electrical). The ECM has been designed to know that the end of the injection pulse must occur before the spark plug ignites. It knows (in degrees before top dead center) when it's going to ignite the spark plug, so it determines that the end of the pulse must occur before the plug ignites, plus a certain margin. It also knows by now how long the injection pulse is going to be, and can calculate, based on engine RPM at the time, when the injection pulse must begin. It will use the DESIRED injection start angle as long as the pulse will complete by the time it needs to. However, the ACTUAL injection start angle used may be earlier because of these compensatory factors. Skewing of the injection start angle is normally not a problem (on an unmodified vehicle being operated within its design parameters), and this process is designed to be dynamic. Extensive self-diagnostics performed by the ECM will detect systemic failures and employ safety measures to avoid engine failure and/or potential vehicle operation safety issues. (1.4T LE2 Direct Injector in head) Effects of aftermarket modifications on fuel demands As previously mentioned, virtually any sort of power adder is going to increase fuel demands. After all, we're making more power generally by putting more oxygen into the engine, which in turn requires more fuel. On top of that, in many cases the fuel mixture has to be made “richer” in order to provide engine reliability at increased power levels. With regard to TRIFECTA's products, the main concern generally has to do with recalibrating the ECM to increase the boost levels provided by the factory turbocharger(s) and studying the impact that will have on the fueling demands under a wide variety of operating conditions. There can also be “downstream” effects of raising the boost levels on the engine. For instance, the ECM employs mechanisms to calculate the temperature of the catalytic converters. It also employs mechanisms to calculate the temperature of the turbocharger units, and in both examples here, may dynamically choose a richer fuel mixture in order to control the temperature of these components to avoid component failure, and/or engine failure (due to excess heat build-up in the pistons or exhaust valves). As mentioned above, these vehicles are generally designed to operate under the most extreme conditions without exceeding the capacity of the fuel system – at factory power levels. At higher power levels, however, the vehicle's fuel system may have insufficient capacity to provide accurate and timely fuel delivery if any of these “downstream” enrichment mechanisms are triggered. In this way, the manufacturer is making it exceedingly difficult to run these engines at higher power levels under all operating conditions. Symptoms of exceeding fuel system capabilities On traditional MPFI engines, the symptom of exceeding the fuel system's capability would be simply that the ACTUAL air to fuel ratio would not equal (would be leaner than) the DESIRED air to fuel ratio. This can be quite disastrous because it would tend to happen when the engine was under the highest load. The leaning out of the fuel system under heavy load will almost certainly cause catastrophic failure of the engine due to the mixture being too lean. On DI engines, this can happen also, but generally what happens is the start of injection angle is so far advanced that the ECM is trying to inject fuel while the exhaust valve is still open from the previous combustion cycle, and/or the ECM is trying to inject fuel while igniting the spark plug at the same time. This results in a terrible combustion pattern, extreme loss of power, and emission of black soot (unburned fuel) out the exhaust. This is, by no means a good operating condition, but the loss of power effectively reduces the likelihood of a major engine failure. However, prior to the loss of power, soot, etc., a fuel system capacity issue can be identified by observing the fuel rail pressure. If the rail pressure starts to drop, it's because the high pressure pump's capacity is being exceeded, the low pressure pump's capacity is being exceeded, and/or some other component of the fuel supply system is not capable of providing the required fuel volume. Furthermore, the ECM has diagnostics for the high pressure pump – if the ACTUAL rail pressure is less than the DESIRED rail pressure for enough time, the ECM will set a trouble code, and generally reduce the available power (reduced engine power mode). This is why there's a fixation on fuel rail pressure in the aftermarket, and rightfully so. Resolving fuel system capacity issues At the end of the day, fuel system capacity issues can be resolved by either reducing fuel demands, or increasing fuel system capacity. Fuel demand reduction (without sacrificing power) can come about by either employing a leaner fuel mixture (generally not feasible) or the disabling of the “downstream” enrichment mechanisms. Some entities may offer “cat delete” pipes and feel that disabling the catalyst protection scheme is an adequate means to reduce fuel demand. We don't agree with this, however, as those schemes are put in place as a whole system (with or without cats) to manage engine component temperatures. Another approach to reducing fuel demand is to simply lower the power levels. This is counterproductive, though, since the intent is to increase power demands. The aftermarket has been slow to produce reliable high pressure pumps with a higher capacity. At the time of writing, there was only recently the introduction of an aftermarket high pressure pump, and only for the Gen 5 V8. There has been some work in the area of modifying the camshaft that drives the high pressure pump to either add more lobes (thus increasing the number of pump cycles per revolution), or increase the pump stroke length (thus increasing the volume of fuel pumped per pump event) by either reducing the camshaft lobe's base circle, or by increasing the lobe size. Any of these are fairly costly modifications, however, and provide only modest increase in fuel system capacity. (2016 Cadillac ATS-V "Cat delete" pipe testing) Active / dynamic rail pressure management TRIFECTA has taken an innovative approach to dealing with potential fuel system capacity constraints. We recognize that the majority of people wishing to turn the boost (and, hence, power) up on their turbocharged DI engines wish also to have non-invasive and reversible modifications to their vehicles. As such, we have developed a software-based solution which resides in the ECM, as part of some of our recalibration products, which actively and dynamically manages the fuel demand vs the fuel system capacity. After tirelessly studying the sources of “downstream” enrichment, we've engineered a solution that allows the ECM to adjust boost and power levels on the fly (hence, dynamically adjusting fuel demands) in response to the other factory-designed enrichment-protection mechanisms that may otherwise cause the fuel system capacity to be exceeded, without requiring the installation of any aftermarket hardware. The factory ECM software, for as excellent as it is, does not provide any sort of construct or mechanism to offer this sort of control over the engine operation. Our embedded software experts developed a customized ECM operating system which analyzes the fuel demands the same thousands of times per second that the ECM does for other functions, and makes boost limit adjustments based on those fuel demands to prevent the fuel system capacity from being exceeded. One of our calibration products to receive this technology is our 2016+ Cadillac ATS-V (with the 3.6L twin turbo V6 engine) calibration product. Being that it’s a “track car”, there may be special concern about whether this technology results in an inconsistent performing vehicle. However, at the time of writing, we had tested the vehicle exhaustively on the street, at the quarter mile track, and under loaded dyno pulls to over 150MPH without seeing a reduction in boost due to engagement of “downstream” enrichment mechanisms. (Cadillac ATS-V undergoing dyno testing) TRIFECTA Research & Technology Group

-

-